Custom Polyurethane Products

Off-the-shelf does not work for everyone. That’s why we make custom parts.

You Won’t Find

Off-The-Shelf Polyurethane

Products Here

Off-the-shelf does not work for everyone. That’s why we make custom parts.

Custom Polyurethane Products

We collaboratively develop custom polyurethane products to meet exactly what you want. This ensures that your product’s form, fit, and function match your application.

Do you want abrasion resistance? Dynamic load bearing? A complex shape? Polyurethane bonded to other materials? We do it.

“Typical” Custom

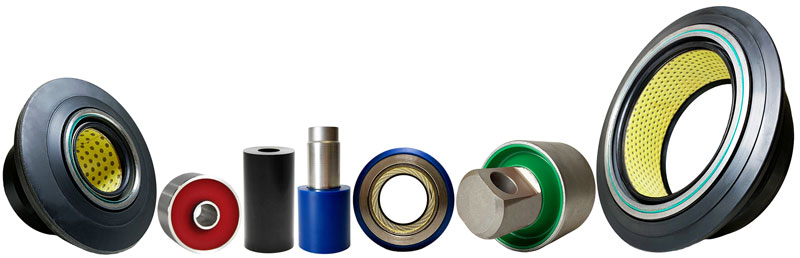

There are several typical applications in which polyurethane performs extremely well. Even though some applications may be typical, custom polyurethane parts are anything but. Each custom polyurethane product is designed and manufactured to meet your unique requirements.

Don’t see an example product pictured here that fits what you want? Don’t worry. That’s the nature of custom! Talk with us about your project.

Wheels and Rollers

Learn More >

Bushings

Learn More >

We Know Polyurethane, How to Mold it, and How to Turn it into Custom Products

We start with your idea and your requirements.

Then we help you with your part’s design so that you get the product performance you need:

☑ Determining the right polyurethane formulation

☑ Designing for manufacturability

☑ Prototypes and testing

Finally it’s time to manufacture. We cast mold, injection mold, and 3D print with polyurethane. Who else does all three under the same roof? Each production method has a sweet spot for processing custom urethane part complexity, production quantities, and polyurethane formulations. With our production versatility, you’ll get the best manufacturing method for your custom urethane products.

Polyurethane is poured into a mold at low pressure and allowed to cure. But don’t let the straightforward process fool you into thinking that cast polyurethane molding makes only simple products.

Molten polyurethane is injected into a closed mold at high pressure. The high-pressure forces the polyurethane to completely fill the mold cavity. The resulting product is net shape, or near net shape, directly out of the mold.

We don’t use a mold in 3D printing. We jump straight from liquid resin to solid product. This creates possibilities to make complex product geometries that would have been costly and time-consuming (or impossible) using traditional manufacturing processes.