Unlike steel springs, the dynamic spring rates of various urethanes can range from 1.25 to 2.5 times greater than their static spring rates, depending on the compound. Also unlike steel springs, a significant percentage of the input energy is converted to heat. By controlling the deflection per cycle we can control the heat buildup due to hysteresis so the urethane is not overheated.

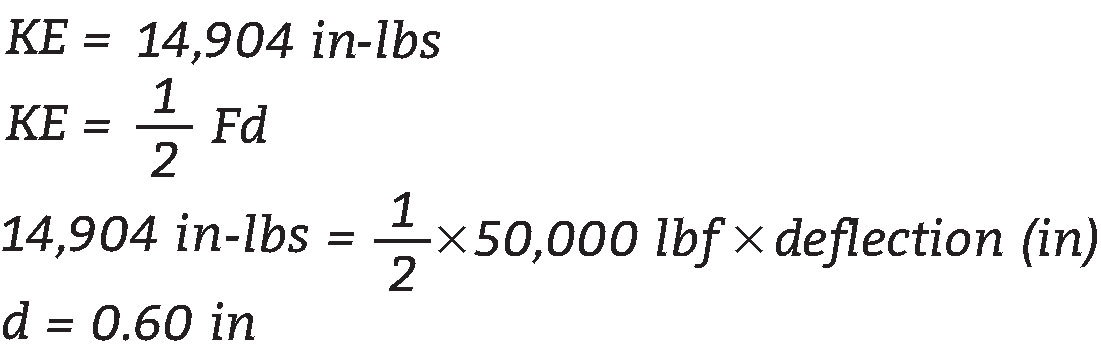

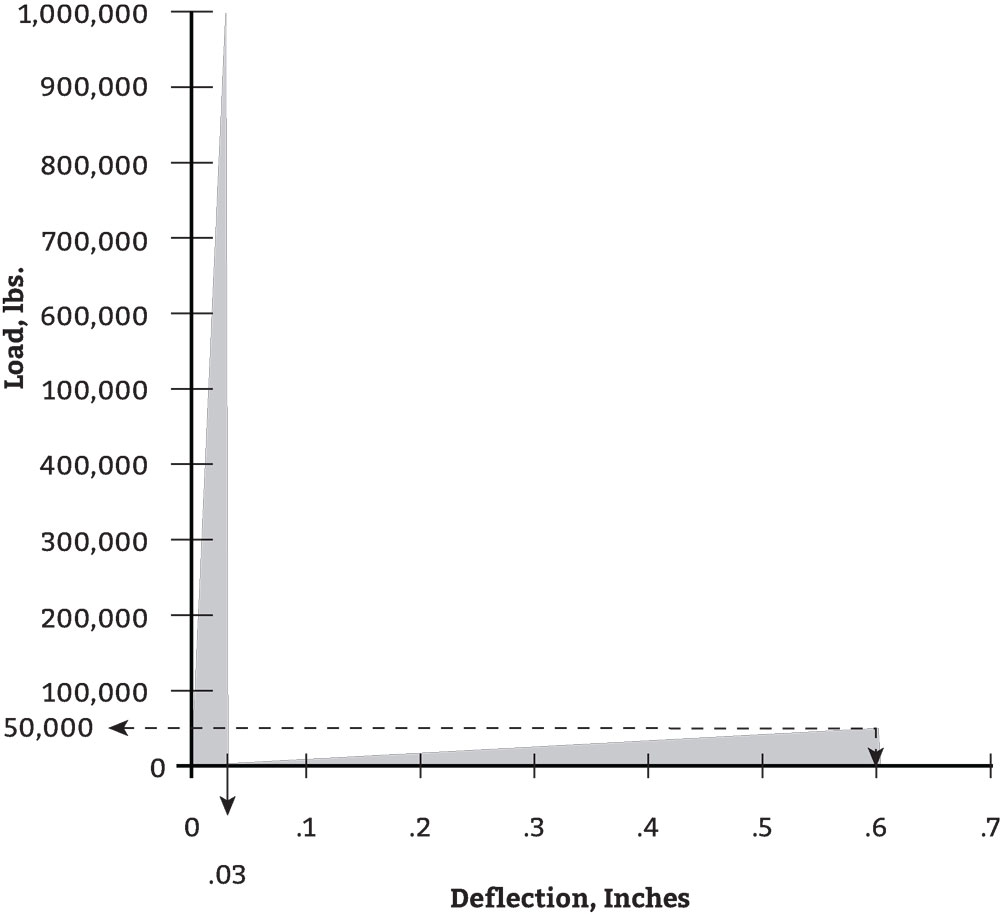

Fortunately, we can simplify the analysis in some applications. Even though urethanes behave in a nonlinear way, we can treat them as linear materials in deflections up to about 15-20%. This allows us to approximate the strain energy, the area under the load-deflection curve, as the area of a triangle with one leg being the reaction force at maximum deflection and the other leg the maximum deflection.

Example:

An 800 pound (362kg) transfer carrier travels at 10 ft/sec and hits a stop once per minute. Without a bumper to decelerate the carrier, the impact force may exceed a million pounds. To protect the machine we should limit the impact or transmitted force to 50,000 pounds by installing a urethane bumper. Due to limited space, the bumper will be 6 inches in diameter by 3 inches long (15cm x 7.6cm), bonded between metal plates. Let’s select the right urethane.

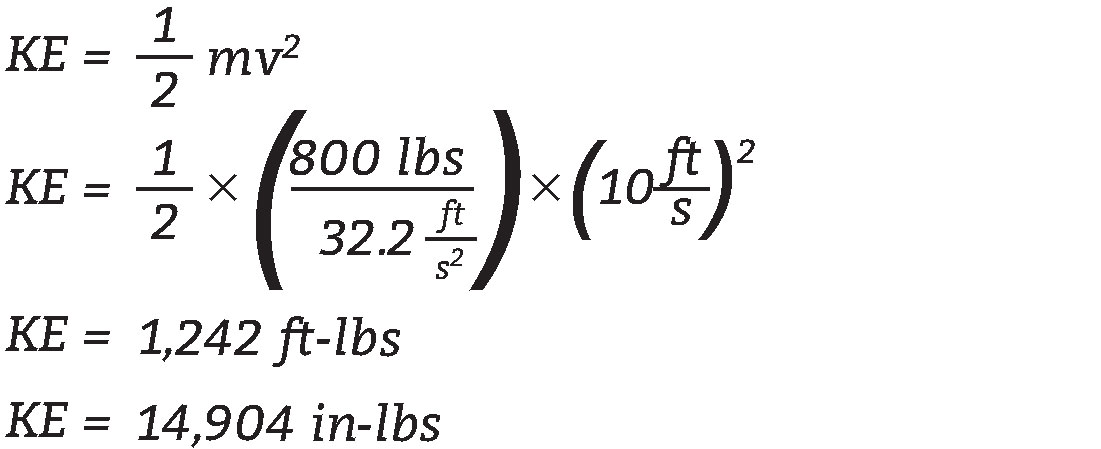

The Kinetic Energy of the carrier is:

These two equal impact loads have the same area under load-deflection curves. The reaction force in one case is 1,000,000 pounds and in the other only 50,000 pounds. This graphically illustrates the importance of deflection in absorbing impact. The urethane in this case is 95A durometer (GC1095).