Polyurethane 3D Printing

An advanced method to produce a polyurethane product that doesn’t use a physical mold (may also be called additive manufacturing or digital molding)

Polyurethane 3D Printing

An advanced method to produce a polyurethane product that doesn’t use a physical mold (may also be called additive manufacturing or digital molding)

Why It Matters

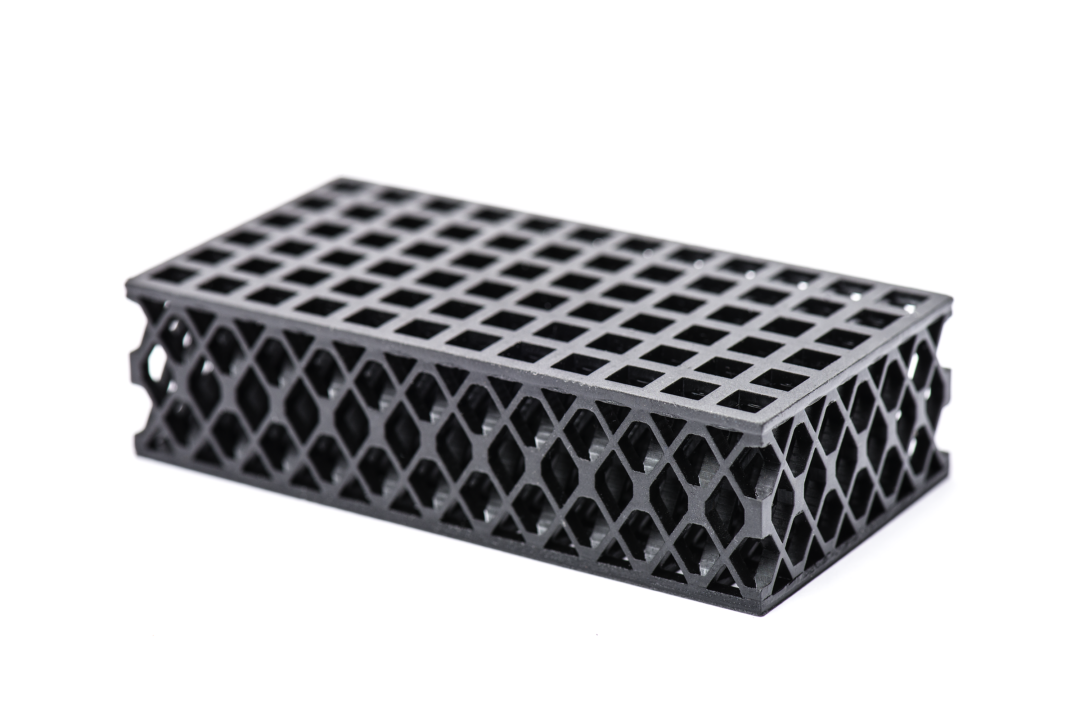

We don’t use a mold in polyurethane 3D printing. We jump straight from liquid resin to solid product. This creates possibilities to make complex product geometries that would have been costly and time-consuming (or impossible) using traditional manufacturing processes.

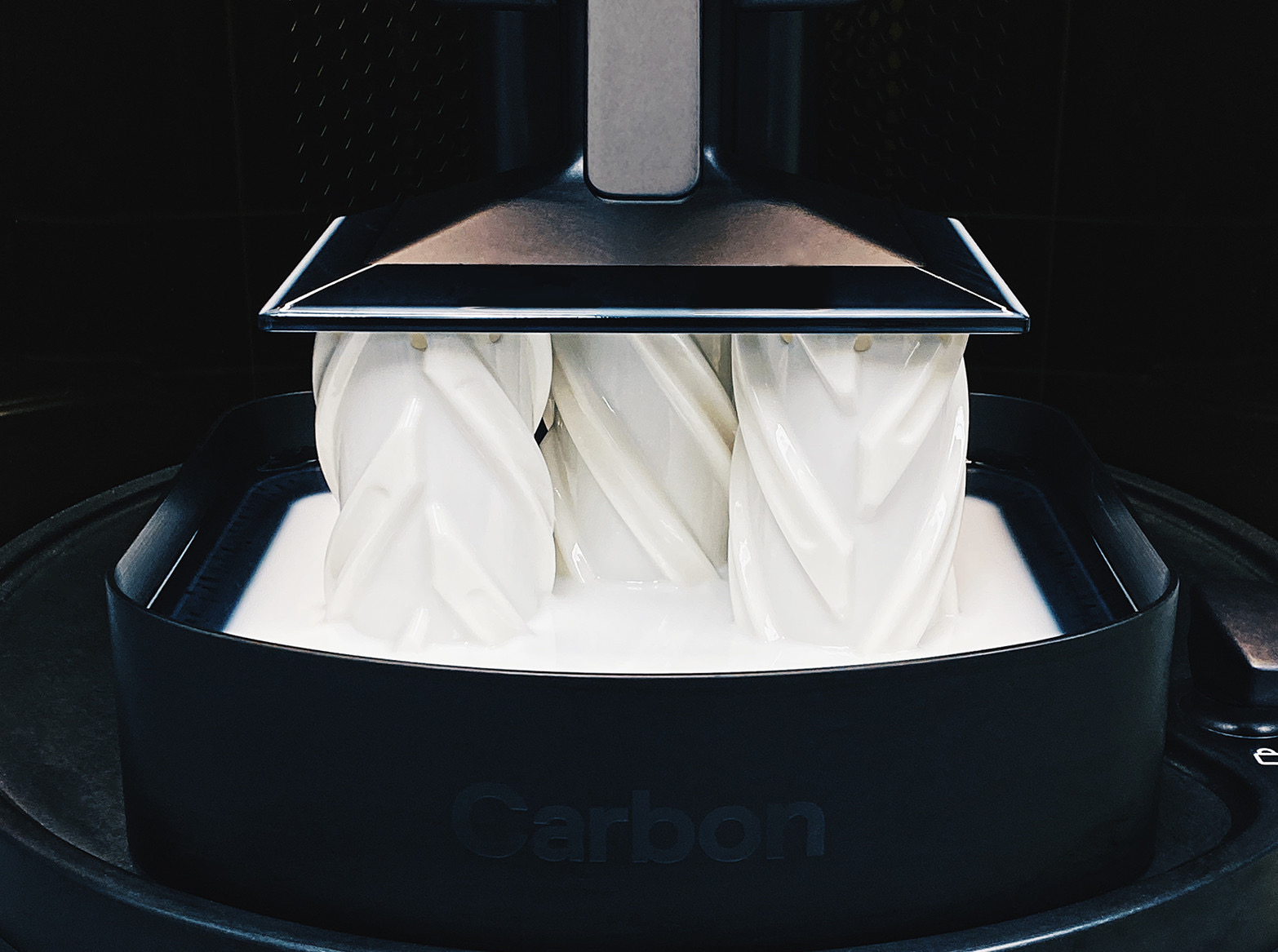

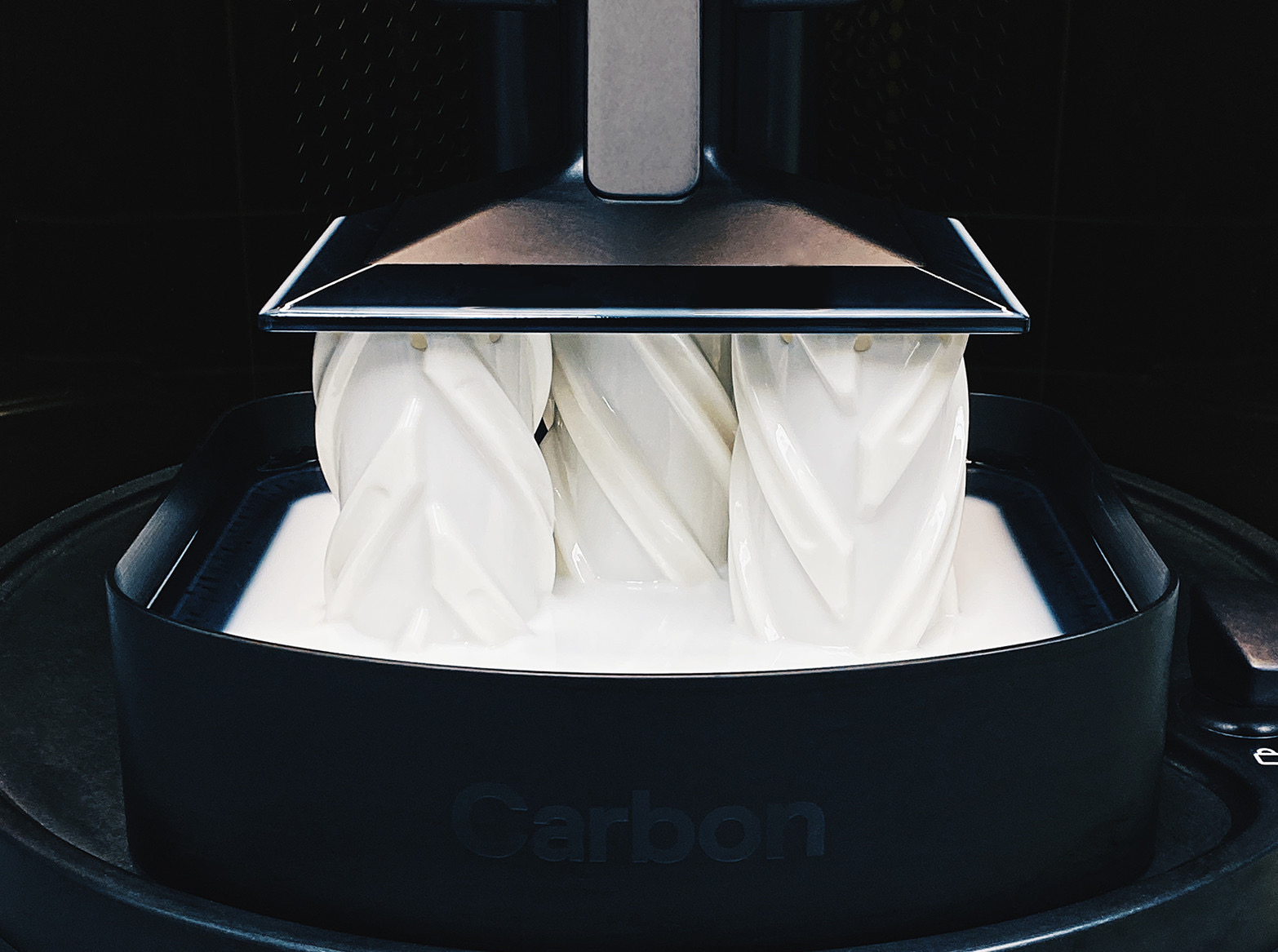

We are partnered with Carbon®, Inc. to offer the latest in latest in urethane 3D printing – Digital Light Synthesis™ (DLS). Carbon develops the materials, technology and processing equipment that make DLS work. We make DLS work for you. We print your custom polyurethane products at production quantity scale.

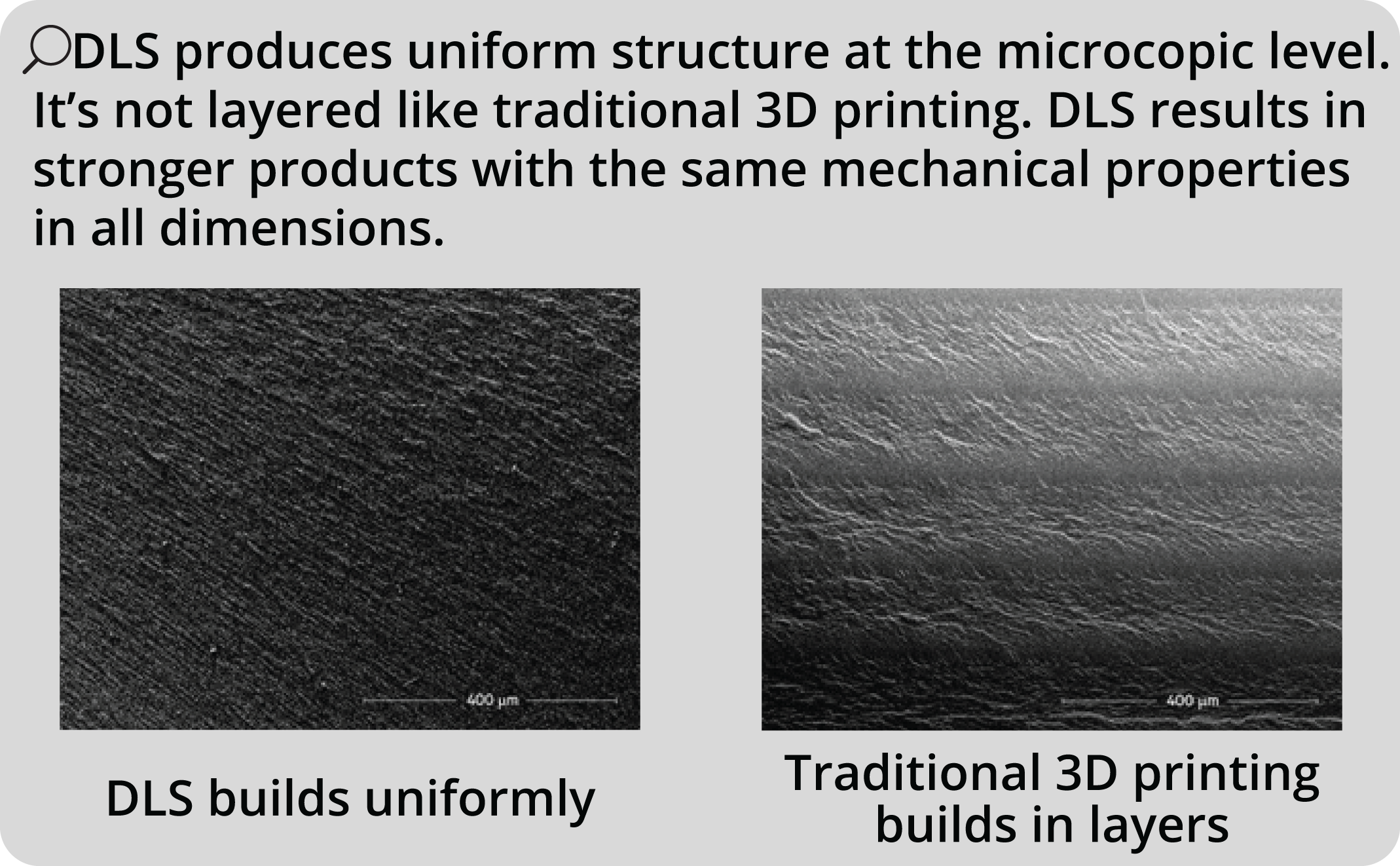

DLS produces products with isotropic mechanical properties and excellent surface finish. This is radically better than other printing methods that fuse together discrete layers of material.

The Gallagher Advantage

We are one of a select few production companies that are partnered with Carbon to use their digital molding technology. We’re proud to be one of the first manufacturers with this capability. Our polyurethane manufacturing know-how means that you will get quality, custom polyurethane products that fit your need.

By the way, we aren’t just dabbling in the technology. We have built what could be considered a factory of the future — a Carbon SpeedCell™ — to enable manufacturing at production quantity scale.

How We Do It

Digital Light Synthesis jumps from resin to product in two stages:

First, the product’s shape is formed by precisely projecting a sequence of ultraviolet images into a reservoir of liquid polyurethane resin. The UV light solidifies only the resin needed to create the required shape.

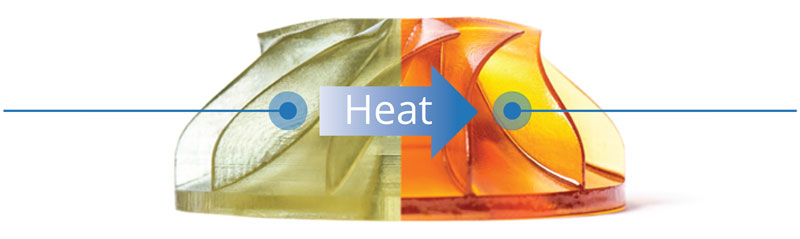

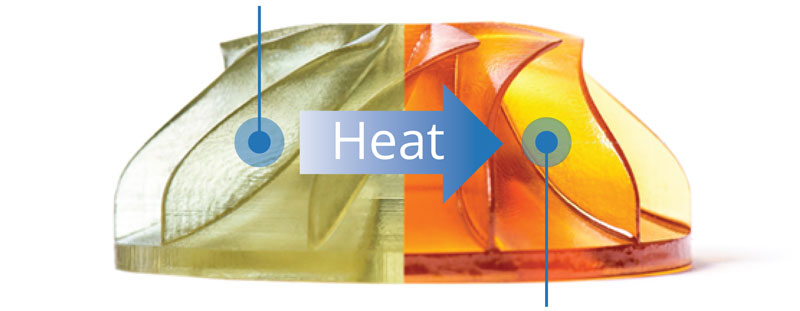

Next, the solid shape is heated in an oven to complete the curing process. Heating causes molecular cross-linking to occur within the thermoset materials. It’s the molecular cross-linking that imparts the engineering-grade performance properties.

First, the product’s shape is formed by precisely projecting a sequence of ultraviolet images into a reservoir of liquid polyurethane resin. The UV light solidifies only the resin needed to create the required shape.

Next, the solid shape is heated in an oven to complete the curing process. Heating causes molecular cross-linking to occur within the thermoset materials. It’s the molecular cross-linking that imparts the engineering-grade performance properties.

Materials To Meet Your Application

With polyurethane 3D printing, multiple resin options offer a range of engineering-grade performance properties to meet your requirements. The resins have been specifically formulated to produce products with isotropic mechanical properties, precise geometry, and excellent surface finish (whether you want smooth or textured).

We have resins that perform similarly to traditional materials, like silicone, polyurethane, polypropylene, acrylonitrile butadiene styrene (ABS), and glass-filled nylon. Hardnesses range from 35 Shore A to 90 Shore D.

Our Most Common Material Options:

Elastomeric Polyurethane

Highly elastic, tear-resistant, and resilient

Comparable to thermoplastic urethanes

Flexible Polyurethane

High impact strength and cycle life

Comparable to polypropylene

Rigid Polyurethane

Versatile, tough, and rigid

Comparable to ABS

Epoxy

Temperature resistant, strong, and tough

Comparable to lightly glass-filled thermoplastics (e.g. 20% GF-PBT, 15% GF-Nylon)

Cyanate Ester

Highly temperature resistant and stiff

Comparable to glass-filled nylon

Elastomeric Polyurethane

Highly elastic, tear-resistant, and resilient

Comparable to thermoplastic urethanes

Flexible Polyurethane

High impact strength and cycle life

Comparable to polypropylene

Rigid Polyurethane

Versatile, tough, and rigid

Comparable to ABS

Epoxy

Temperature resistant, strong, and tough

Comparable to lightly glass-filled thermoplastics (e.g. 20% GF-PBT, 15% GF-Nylon)

Cyanate Ester

Highly temperature resistant and stiff

Comparable to glass-filled nylon